The three-way catalytic converter of an automobile is one of the key components to control and reduce the emission of pollutants, however, due to the harsh working environment and the limitation of service life, the traditional three-way catalytic converter is often affected by corrosion and fails. To solve this problem, the researchers proposed a new solution based on metal carriers, which provides higher corrosion resistance for three-way catalytic converters by selecting the appropriate metal and adopting advanced coating technology. This article will detail the new solution for corrosion resistance of automotive three-way catalytic converters based on metal carriers, including the selection of metal carriers, the application of coating technology, and the evaluation of corrosion resistance.

Automobile exhaust emissions are one of the serious sources of environmental pollution, and three-way catalytic converters, as a key device to reduce harmful gas emissions, are widely used in modern automobiles. However, because the three-way catalytic converter works in the high-temperature, high-humidity and sulfide-containing exhaust gas environment for a long time, it is easy to be corroded, which reduces the catalytic effect and even fails. Therefore, the development of a three-way catalytic converter with better corrosion resistance has become an important topic for researchers.

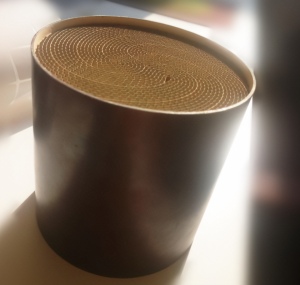

The metal carrier is the main component of the three-way catalytic converter, and selecting the appropriate metal is crucial to improve the corrosion resistance of the three-way catalytic converter. Common metal carrier materials include aluminum alloys, cast iron and stainless steel. Studies have shown that aluminum alloys have good thermal conductivity and mechanical properties, but oxidative corrosion is easy to occur in high temperature and high humidity environments. In contrast, stainless steel has good corrosion resistance but poor thermal conductivity. Therefore, in order to comprehensively consider thermal conductivity and corrosion resistance, some researchers have proposed the use of composite metal supports, such as aluminum alloys and stainless steel composites.

In order to further improve the corrosion resistance of the three-way catalytic converter, coating technology is widely used on the surface of metal supports. The coating can provide an extra layer of protection against corrosion factors in the environment. Commonly used coating technologies include thermal spraying, electrochemical deposition, and physical vapor deposition. Studies have shown that the use of suitable coatings can effectively improve the corrosion resistance of metal carriers and extend the service life of three-way catalytic converters.

The evaluation of the corrosion resistance of three-way catalytic converters based on metal supports can be carried out by a variety of methods. These include wet flue gas environment simulation experiments, electrochemical corrosion tests and catalytic activity tests. Through these evaluation methods, the effect of anti-corrosion coatings can be quantitatively evaluated and scientific basis can be provided for improving the corrosion resistance of three-way catalytic converters.

The new solution for corrosion resistance of automotive three-way catalytic converters based on metal carriers provides an important guarantee for improving the efficiency of automobile exhaust gas treatment. By selecting the right metal carrier and adopting advanced coating technology, the corrosion resistance of the catalytic converter can be effectively improved and the service life can be extended. Future research can further optimize the metal carrier and coating technology, improve the corrosion resistance of the three-way catalytic converter, and make greater contributions to environmental protection and the sustainable development of the automotive industry.

Post time: Sep-13-2023